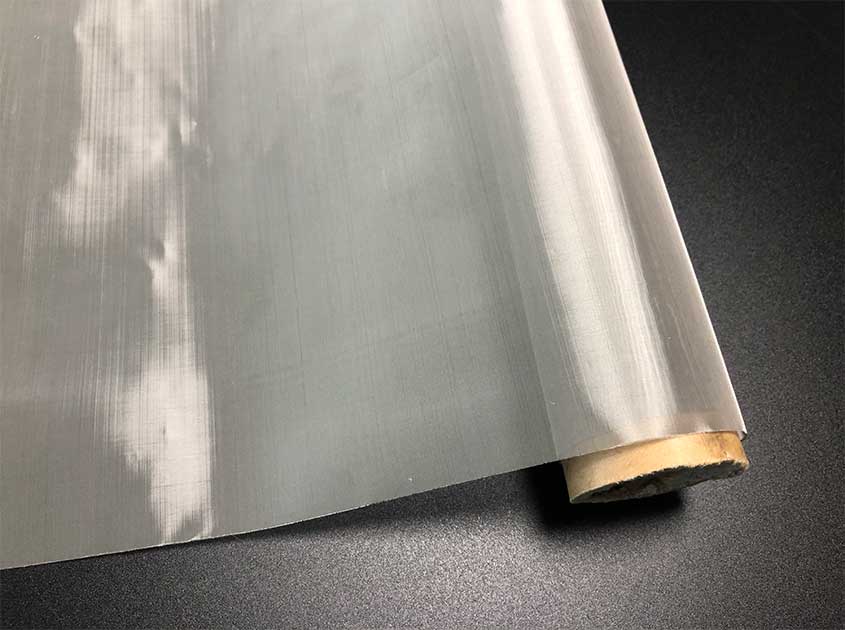

Safety performance evaluation of stainless steel wire mesh: equal emphasis on protection and reliability

As an important safety protection material, stainless steel wire mesh plays a key role in all walks of life. However, ensuring the safety performance of stainless steel wire mesh is critical to its effectiveness. This article will delve into the safety performance evaluation of stainless steel wire mesh, focusing on its protection performance and reliability to ensure its effective use in various application scenarios.

Material selection and certification:

The safety performance of stainless steel wire mesh depends on the selection and quality of the material. It is important to choose a high-quality stainless steel material, such as 304 or 316 grade stainless steel, to ensure that it has good corrosion resistance and weather resistance. In addition, it is also key to verify the qualifications and certifications of suppliers and manufacturers, such as ISO certification, quality management system certification, etc., to ensure that stainless steel wire mesh meets international standards and safety requirements.

Strength and durability testing:

Stainless steel wire mesh must withstand various external pressures and environmental conditions. Strength testing is a key step in evaluating the tensile strength and compressive capacity of stainless steel wire mesh. The endurance and reliability of stainless steel wire mesh can be evaluated by conducting tensile test, impact test and pressure test, etc. In addition, the durability test can simulate the effect under long-term use conditions to ensure that the stainless steel wire mesh can be durable in various environments.

Protection Performance Evaluation:

The performance of stainless steel wire mesh in terms of safety protection is crucial. Evaluating its protection performance needs to consider the requirements of different application scenarios. For example, in the field of construction, stainless steel wire mesh is used to protect areas such as windows, balconies and stairs, and its protective performance evaluation should include impact resistance, climbing resistance and damage resistance. At the same time, in the industrial field, stainless steel wire mesh is used in applications such as screening, filtration and isolation, and its protection performance evaluation should include filtration accuracy, corrosion resistance and high temperature resistance.

Regular inspection and maintenance:

In order to ensure the long-lasting and effective safety performance of stainless steel wire mesh, regular inspection and maintenance are essential. Regularly inspect stainless steel wire mesh for appearance and structural integrity, and for corrosion, damage, or looseness. Clean and repair when necessary, and replace damaged parts in time to maintain the integrity and reliability of the stainless steel wire mesh.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China